It is a process that has already existed for a certain lapse of time, but that is expected to boom in the coming years. The diffusion of the culture of the 3D printing technology is involving more and more private consumers and companies.

This is why Libe has introduced this type of processing within its work package.

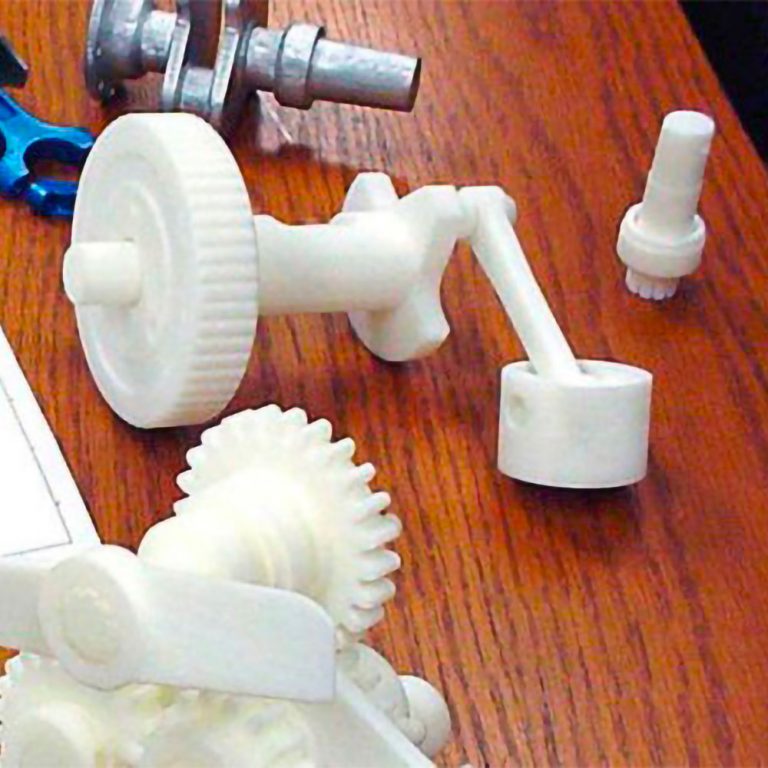

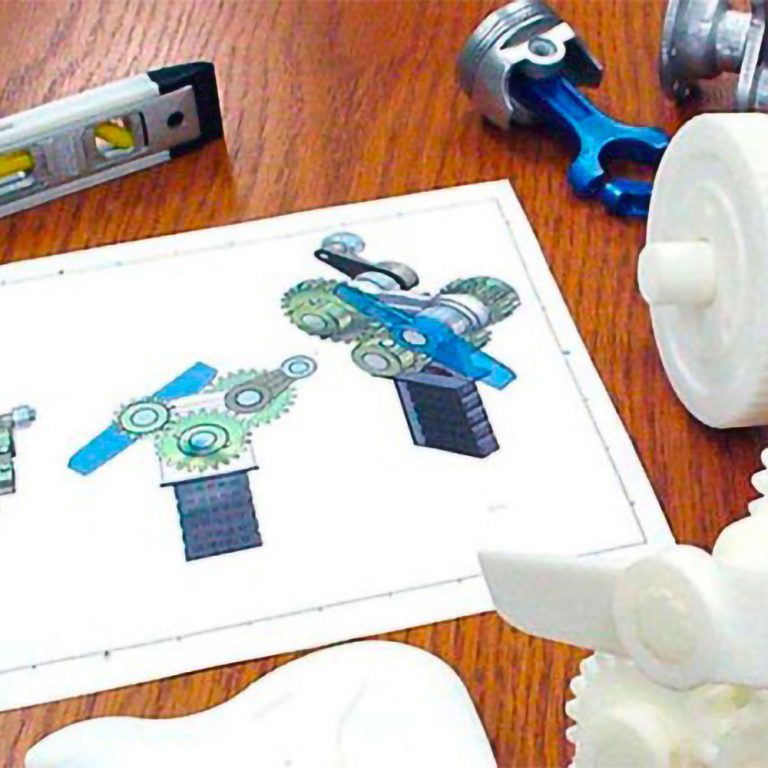

We are able to prepare models for the construction of molds for resin objects and we have started to offer this process to a wide range of Customers for the prototyping of models that are subsequently molded, for example, by injection.

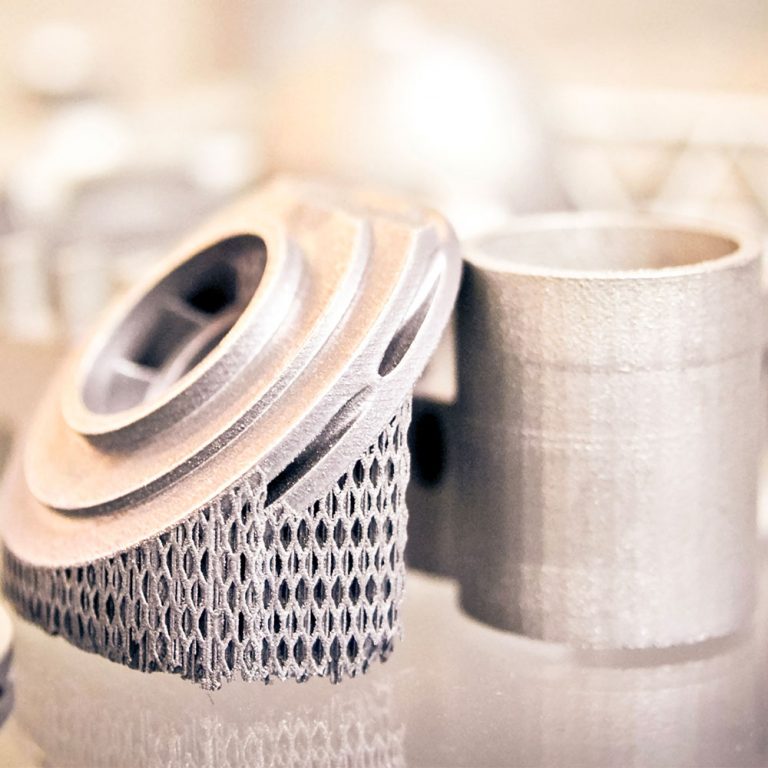

Thanks to the available field of work format 250x250x250mm we can also perform mechanical parts intended for multiple fields of application. “The advantages are many but they can be summarized essentially in the reduction of the execution times of the parts and an extreme possibility of personalized workgs. Entering the 3D printing world has allowed us to acquire new Customers and satisfy new industrial sectors for prototype production or small, medium and large-scale production. “