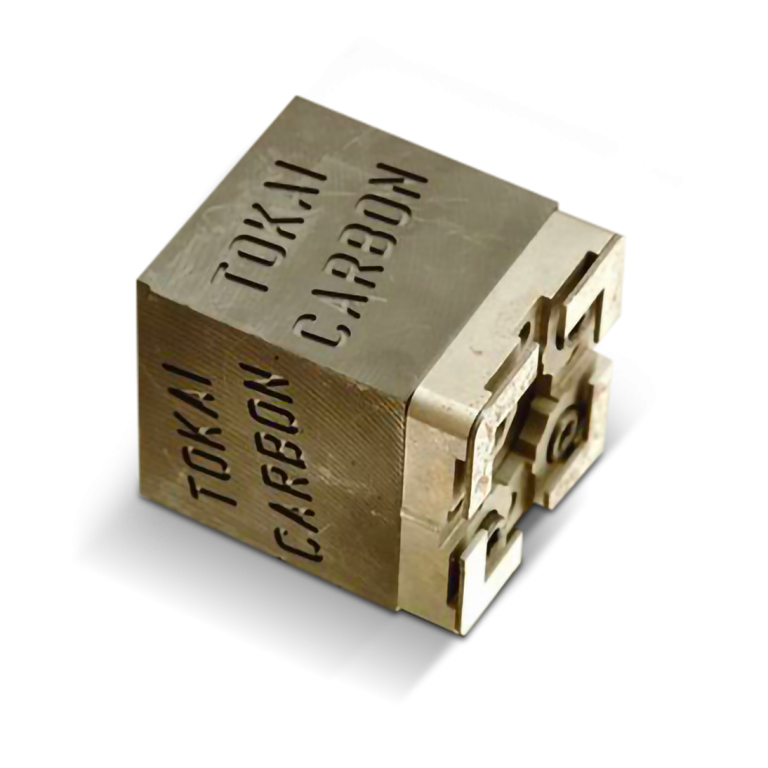

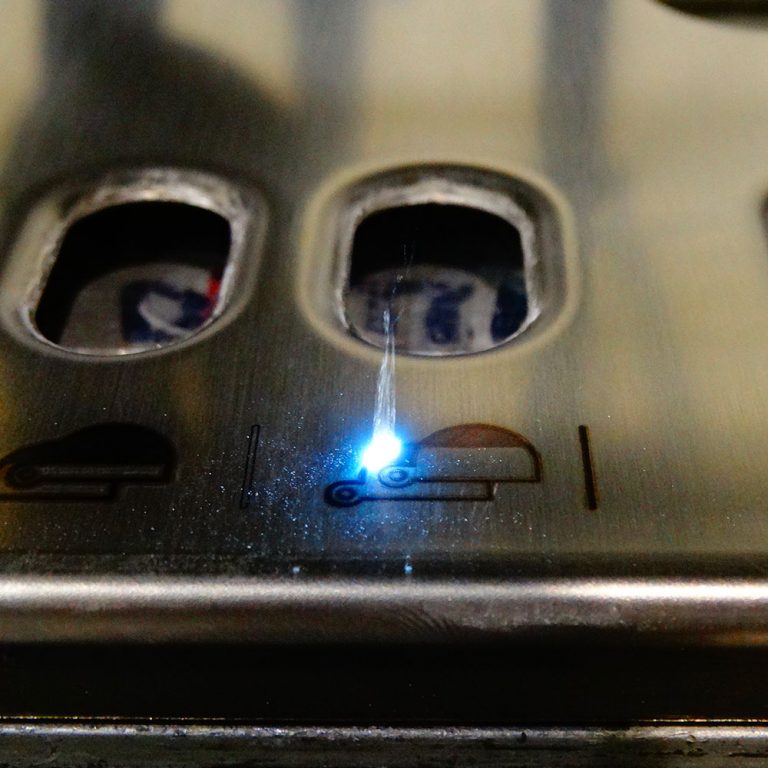

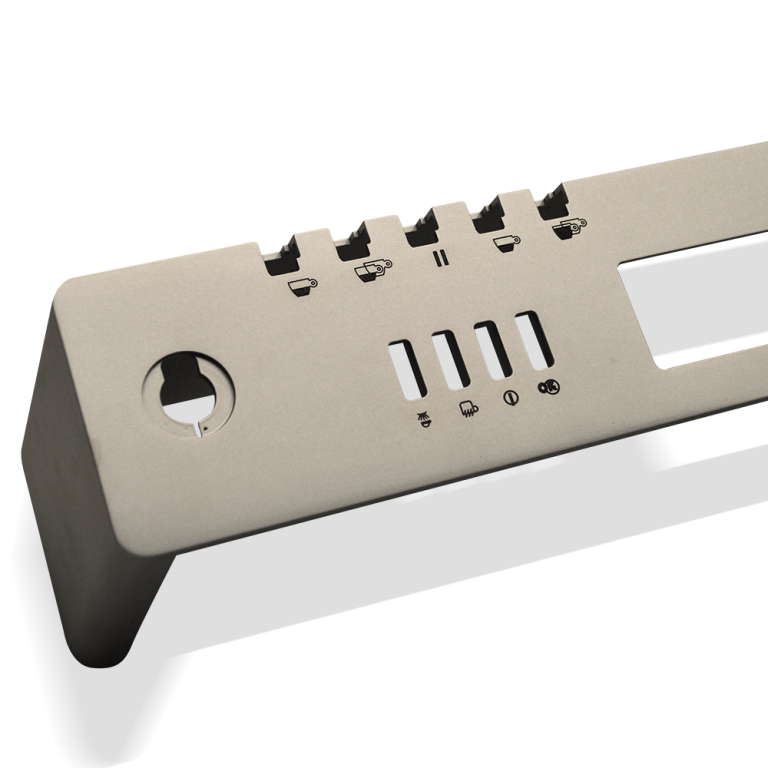

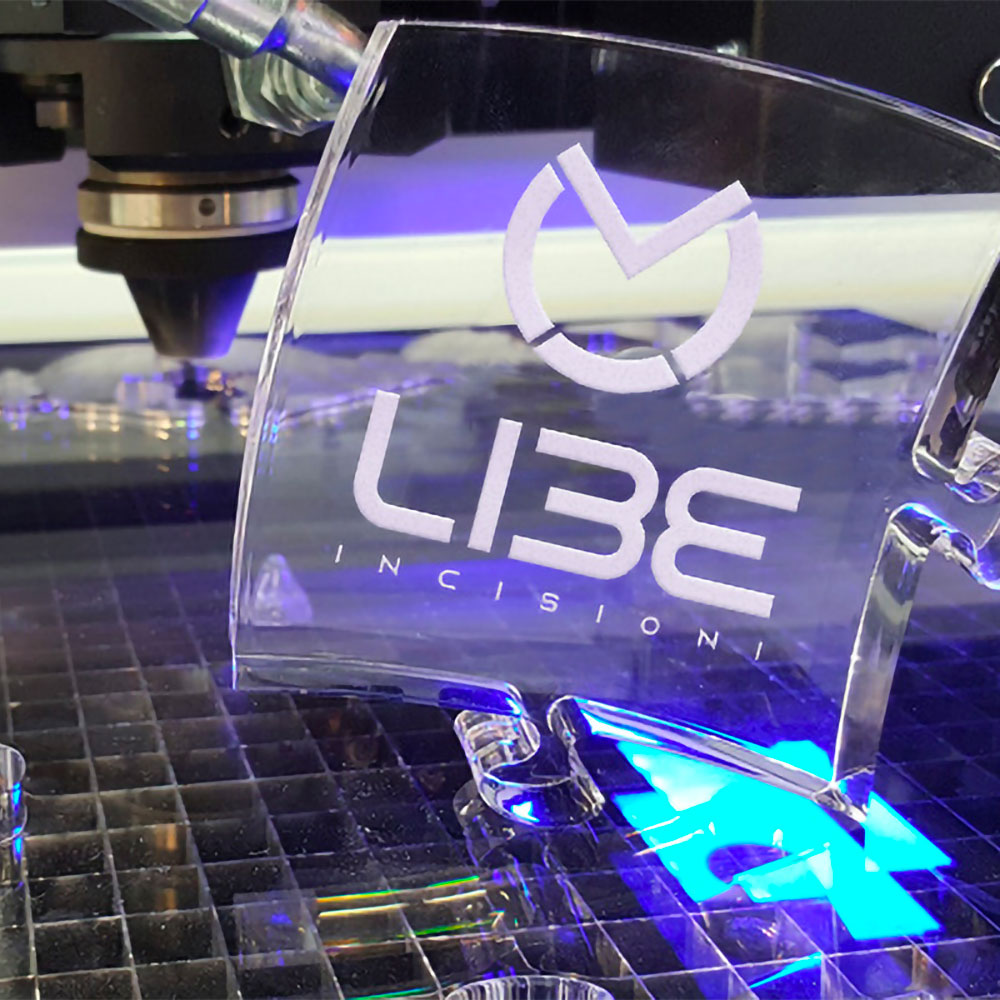

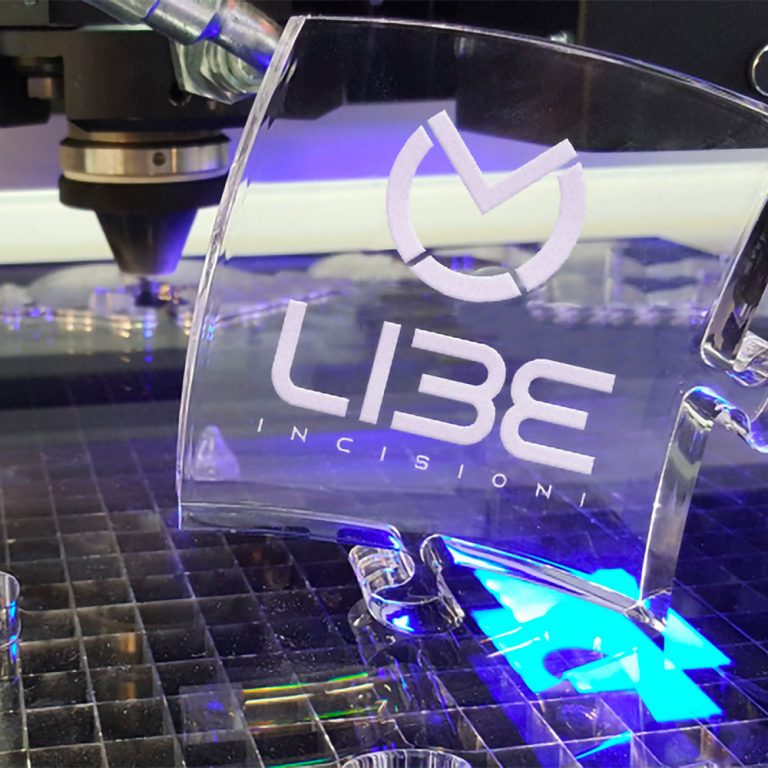

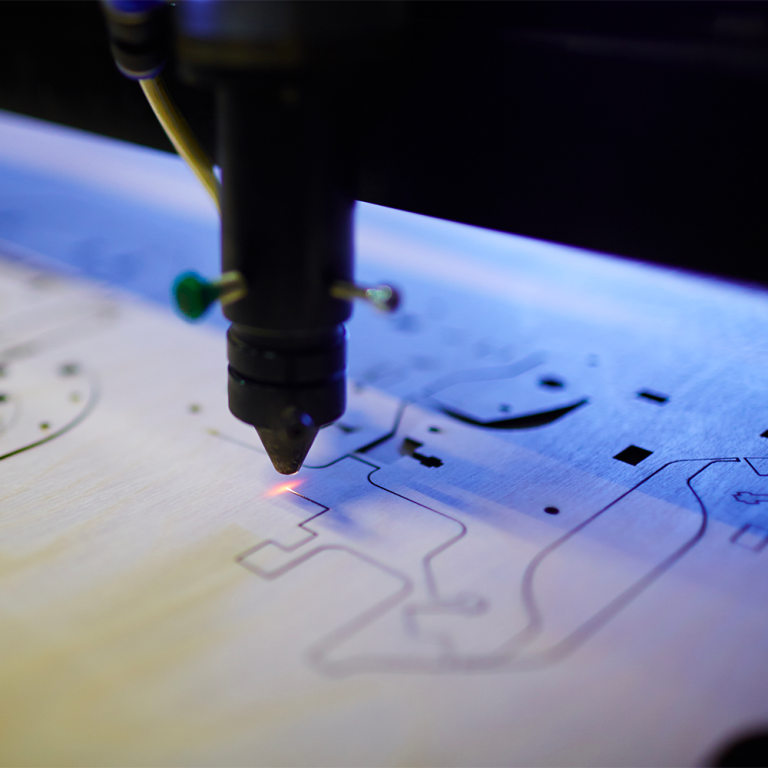

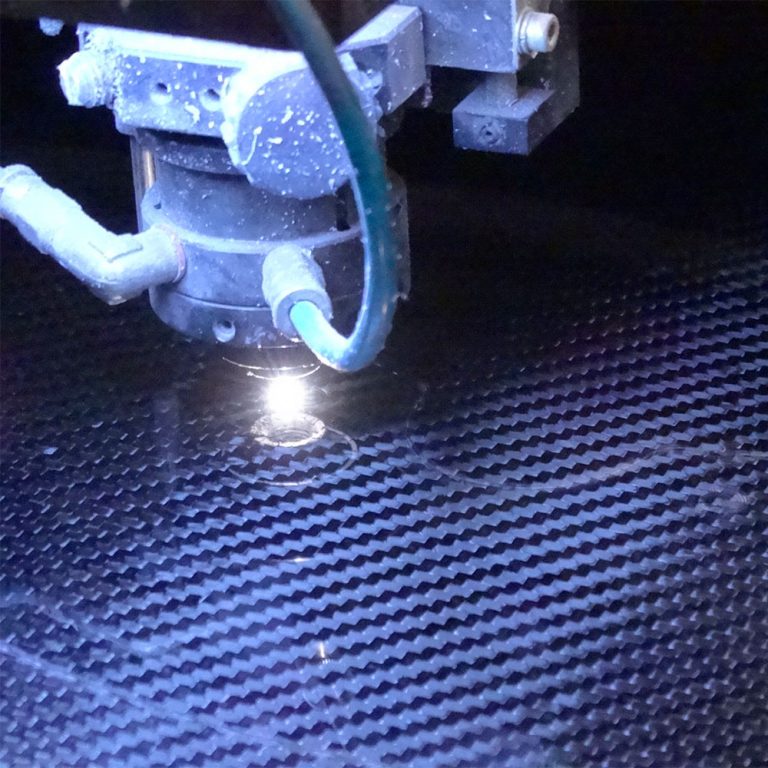

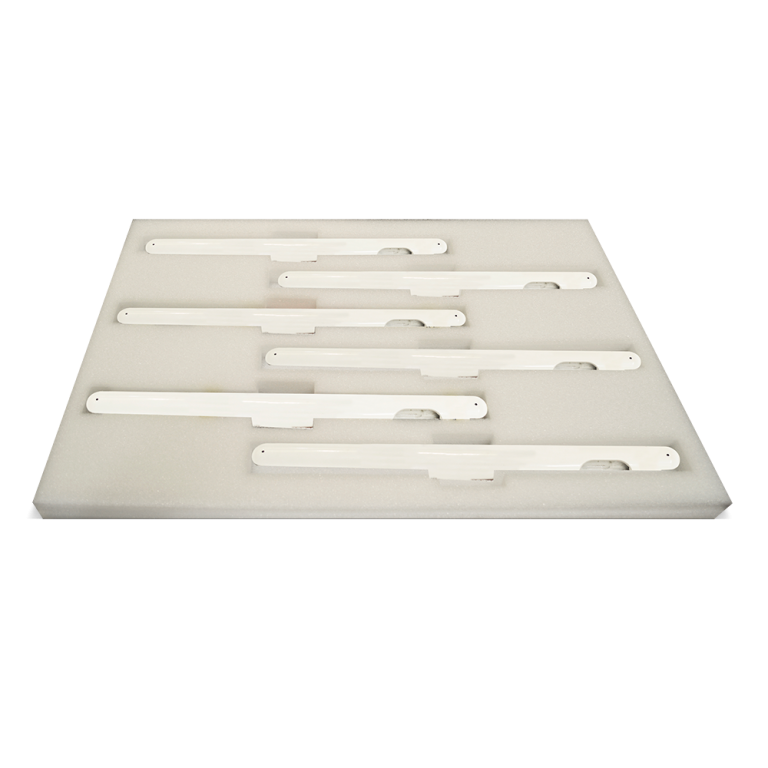

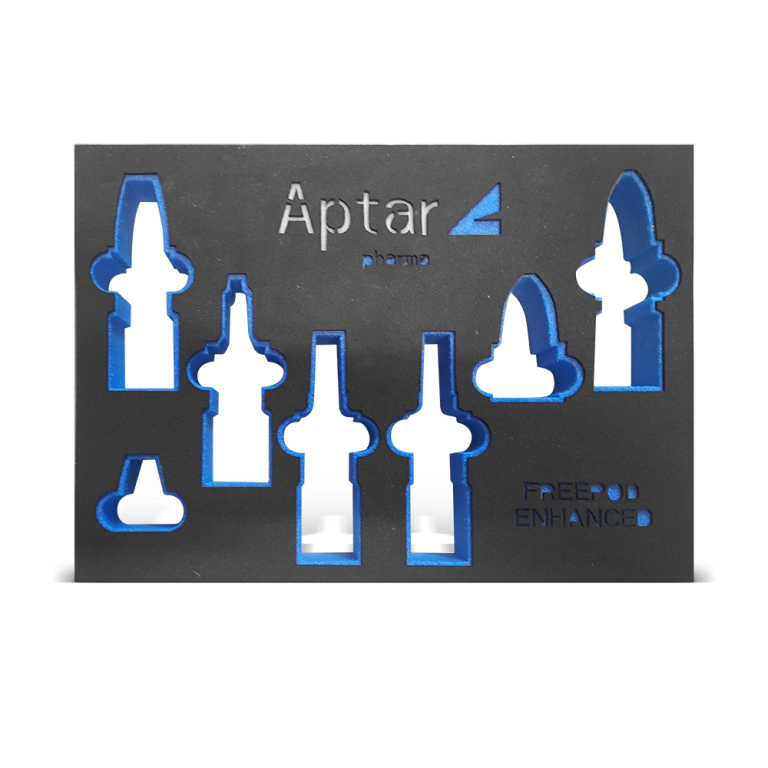

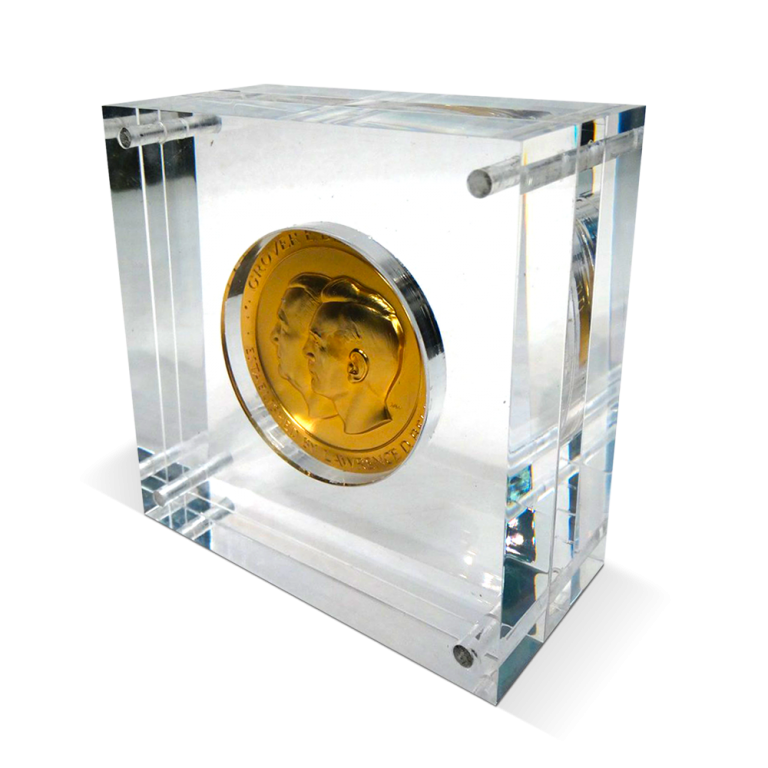

Laser marking is a processing technology featuring indelibility and versatility. Weatherproof, it is ideal for working applications in contact with solvents or subject to high wear. Its versatility finds an excellent field of application in all those situations characterized by numerical variants such as sequential codes, bar codes and QR codes. With the use of laser markers, Libe processes the most varied materials, from plastic to metal, from glass to wood; solutions that embrace many sectors, from industry to crafts.